When people think about construction, most imagine heavy machines, concrete mixers, and tall cranes shaping the skyline. But behind all that noise and action lies something far less visible, yet just as powerful: planning the steel bars that keep the whole thing standing. This step is often overlooked by outsiders, but for engineers and builders in the USA, it’s the backbone of a safe, solid structure.

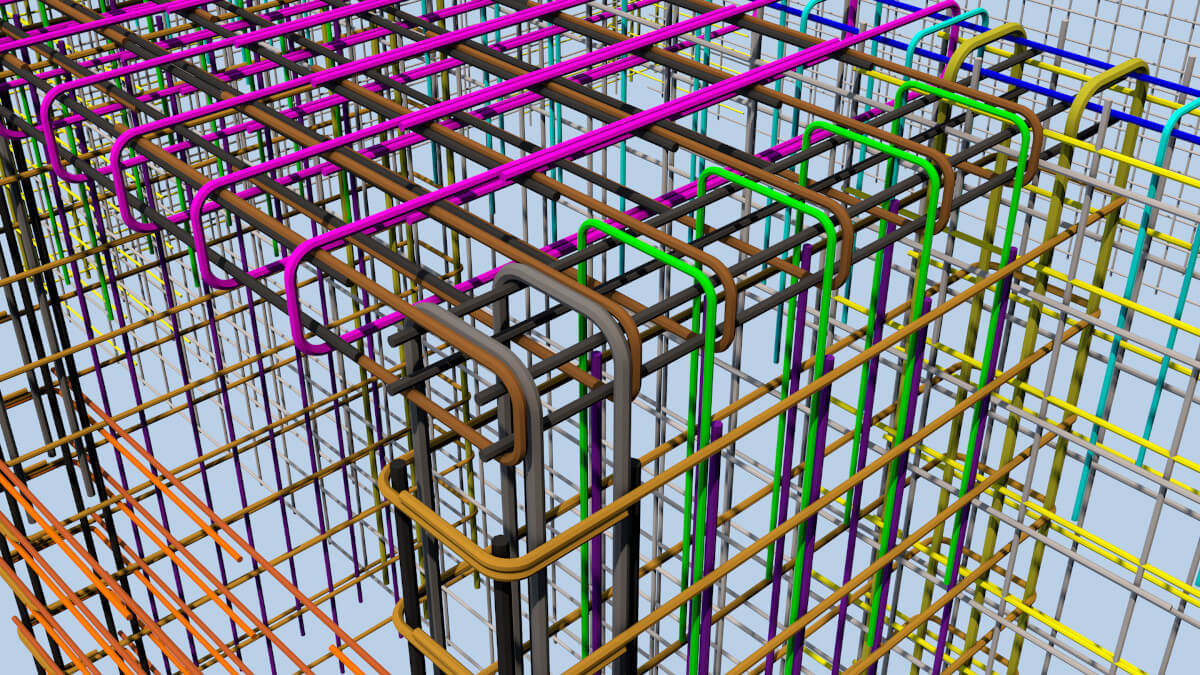

Steel bar plans are not just about where to put a rod here or a bend there. They’re about understanding load paths, structural forces, and ensuring that every column, slab, and wall can do its job without failing. Cracking the “art” behind these plans means balancing creativity, calculations, and practicality.

The Roots of Reinforcement in American Building Culture

In the U.S., reinforced concrete has shaped much of the built environment—from highways to skyscrapers. Ever noticed how bridges stretch across rivers without trembling under thousands of cars each day? That strength doesn’t come from concrete alone. It’s the hidden steel skeleton inside.

What makes the American approach different is the mix of codes, safety regulations, and regional variations in climate. A building in California, for example, demands earthquake resistance. In Florida, the same structure must battle humidity and hurricanes. This local adaptation of steel bar planning is what makes it an art form rather than just a checklist.

Step-by-Step but Never Cookie-Cutter

If you talk to engineers about steel reinforcement, they’ll often smile and say, “It’s never the same twice.” And they’re right. While textbooks outline the theory, real-world projects throw curveballs—soil conditions, client demands, weather challenges, and budget restraints.

Here’s how professionals usually break it down:

- Understanding Loads: Before a single bar is placed, engineers study the loads. Dead loads, live loads, seismic forces—each tells part of the story.

- Translating into Drawings: This is where creativity meets accuracy. Drawings show exactly where each steel bar must go, bend, or overlap.

- On-Site Adjustments: Plans look good on paper, but reality often demands tweaks. A smart engineer knows when to adjust without compromising safety.

This balance between precision and adaptability is what separates standard work from exceptional craftsmanship.

Where Technology Meets Experience

One reason steel bar planning in the U.S. has advanced so much is technology. Software today can run detailed simulations that highlight stress points and potential failures. Yet, even with the best tools, experience remains irreplaceable.

That’s where specialists step in, offering rebar detailing services that bridge the gap between design and execution. The real magic happens when technology blends with years of on-site wisdom. A seasoned detailer can spot things in a design that software alone might miss.

The Silent Role of Footing

While most eyes focus on beams and slabs, the foundation quietly carries the burden. Every structure stands or falls on its footing. This is why footing steel placement requires careful consideration, and here’s where footing rebar comes into play. Placing reinforcement correctly at this stage determines whether the building will last decades or crack within years. It’s not dramatic, but it’s vital.

Mistakes that Cost Time and Money

What happens when steel bar planning goes wrong? Delays. Extra costs. Sometimes even safety risks. Here are common pitfalls American contractors warn against:

- Miscommunication between designers and site teams.

- Ignoring local building codes.

- Overlooking climate-specific challenges.

- Rushing detailing without peer review.

The fix? Clear communication and double-checking every plan before the steel hits the site. A single misstep in detailing can create ripple effects that stall the entire project.

American Builders Know It’s a Team Sport

Here’s something many don’t realize—steel bar planning isn’t just about engineers. It’s teamwork. Architects, contractors, structural engineers, and field workers must stay in sync. When they don’t, mistakes slip in.

For example, an architect may dream of wide open spaces with fewer columns. A structural engineer must then figure out how to make that possible without compromising safety. Steel detailing is the language that translates these big ideas into something builders can actually construct.

Local Relevance: How the U.S. Construction Scene Shapes Detailing

In the United States, construction projects often vary wildly by region. Northern states battle snow loads, while southern states brace against storms. Midwest soils shift differently than coastal sands. All these factors influence bar placement and reinforcement style.

Local consulting firms and engineering groups often bring this regional expertise. They don’t just design; they understand the terrain and conditions first-hand. That’s why companies focusing on steel detailing within U.S. markets often gain trust quickly—they offer practical knowledge that outsiders might miss.

The Human Side of the Craft

Behind every bar drawn on a plan is a human decision. Someone sat at a desk, studied soil reports, checked load calculations, and imagined how real people will use the building decades later. There’s a quiet responsibility that detailers and engineers carry. They know that lives depend on their accuracy.

Many seasoned professionals talk about the pride they feel driving past a bridge or building they worked on. To the world, it’s just another structure. But to them, it’s proof of years of hard work, careful planning, and unseen dedication.

Why the Future Looks Exciting

Looking ahead, sustainable construction is reshaping how steel is used in American projects. Recycled steel, eco-friendly concrete mixes, and advanced 3D modeling are becoming the norm. The goal is not just strength but efficiency and environmental responsibility.

Younger engineers entering the field are also blending traditional expertise with digital tools. They’re learning from mentors while pushing the industry into a future where mistakes are minimized, costs are optimized, and structures stand taller and safer than ever.

Bringing It All Together

Cracking the art of steel bar planning in the U.S. isn’t about memorizing formulas. It’s about blending local expertise, human creativity, and modern tools. Every project is a puzzle with its own rules, and those who master the craft know how to adapt.

If there’s one thing to take away, it’s this: the hidden steel inside concrete isn’t just metal. It’s the quiet strength that makes everyday life possible, from the homes we live in to the highways we drive across.

Local Insight You Can Trust

When it comes to American projects, having a partner who knows the local building environment makes all the difference. Firms like Strand Consulting Corporation specialize in blending technical expertise with regional knowledge. They don’t just design; they guide builders through the tricky maze of codes, climate demands, and real-world challenges.

And that’s where the art really shows itself—not just in lines on a drawing, but in the safe, lasting structures that rise because of them.